Heat Seeker

Reduce system complexity and related balance-of-plant costs by avoiding conventional thermal balancing of SOE stacks.

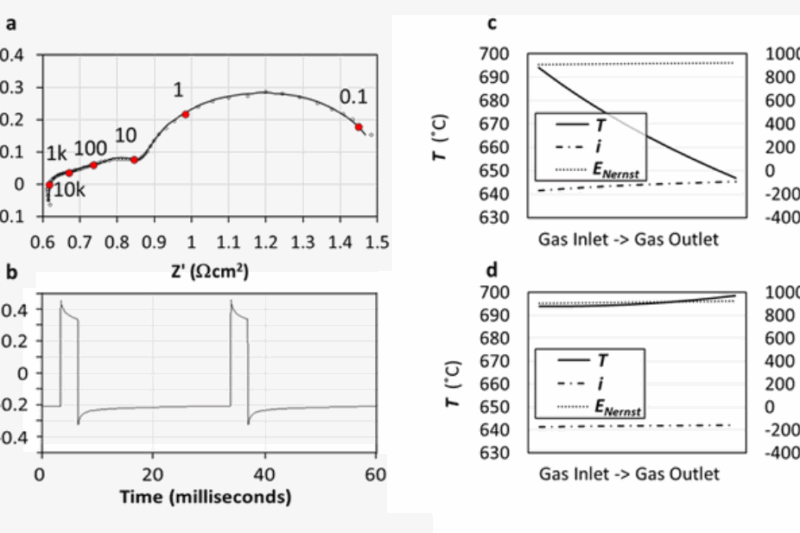

In the project a model is developed and used to simulate temperature and thermomechanical stress in SOEC stacks operated with the patented AC:DC operation technology (developed in the AC:DC and DynEl projects). The model was used to find optimal operation conditions for AC:DC operation for SOEC stacks. The model was used to obtain a detailed understanding of the AC:DC method and find optimal operation conditions for the operation method. Further, the method is used to demonstrate that conventional thermal balancing of SOEC stacks can be avoided, i.e., that a large air-flow can be avoided to control the stack temperature. This reduce system complexity and related cost of balance-of-plant components.

Further, sulphur adsorption/desorption during AC:DC operation was modeled, and test results from single cell and a 1 kW test was analysed. The model was used to describe optimal frequency, shape and amplitude for the AC:DC operation method for maximized SOEC lifetime, reduction of thermomechanical stress, and sulphur tolerance.

UPDATE: Details of this work can be found under the published report on Science Direct.

Electrothermally balanced operation of solid oxide electrolysis cells – ScienceDirect

Project info

InnoBooster project ‘Styringsmetode til Højtemperaturelektrolyseanlæg – Heatseeker‘

Mar 2019 – Mar 2020

485,000 DKK

Innovation Fund Denmark: case no. 8062-01638B